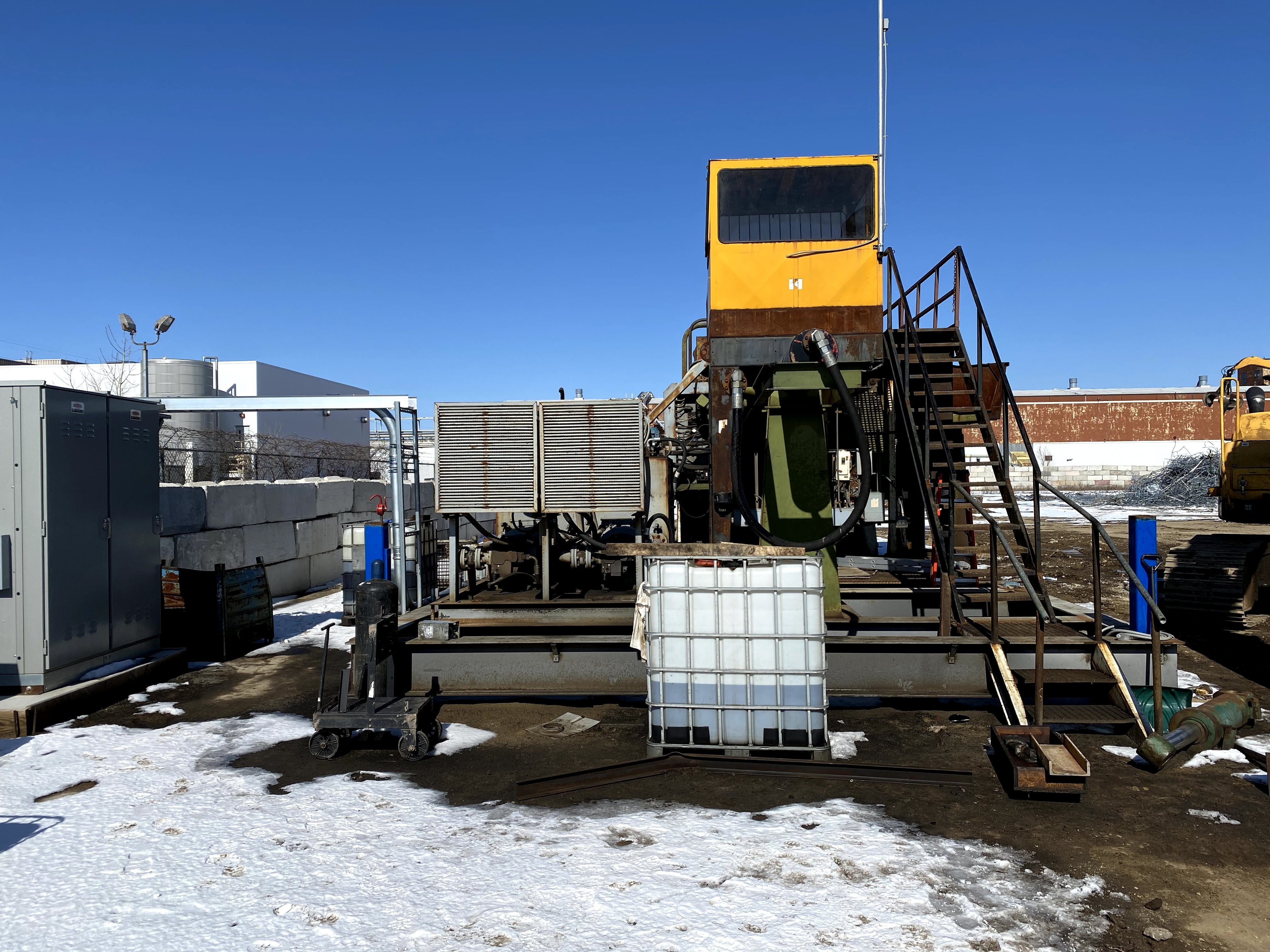

Balers are particularly sensitive to cold temperatures. Oil viscosity changes, seals stiffen, and components cycle slower if systems are not prepared.

Key winter maintenance tips include:

- Allowing adequate warm-up time before full operation

- Using cold-weather hydraulic oil where applicable

- Inspecting hoses, fittings, and seals for brittleness

- Protecting control panels from condensation

- Monitoring baling wire for brittleness in freezing temps

Preventative maintenance in winter is less about fixing failures and more about preventing them before they happen.

BRT regularly supports customers with winter-specific service checks to keep balers running safely and consistently.